Form of the prototype acceptance test report. Requirements and test methods

IN recent years The issue of acceptance testing is very acute. Many people believe that standards in our country are used on a voluntary basis, and the Technical Regulations do not provide direct indications of the need for acceptance tests. There are also such judgments: why invest extra money if you still need to issue a certificate. Or: permission to use may not be obtained, acceptance tests are also an unnecessary procedure, etc.

Let's try to figure it out.

Technical regulations

Since mid-February 2013, the long-awaited document came into force: “On the safety of machinery and equipment” TR TS 010/2011. It contains direct instructions to guarantee safety when design work and subsequent production. That is, the conversation is about the need to determine and establish the acceptable risk for the machine and/or equipment. In this case, the level of security must be ensured:

- a set of calculations and tests that are based on proven methodological developments;

- completeness of development and research work;

- the manufacture of the machine and/or equipment must be accompanied by tests specified in the attached design (project) documentation.

That is, it is clear that both the design organization and the manufacturer are obliged to test the object. They are provided for in the design documentation and must be implemented before certification (procedures confirming compliance). The fact of declaration is obvious - the presence of a document about own tests carried out before the confirmation procedure. But it is not clear what tests are meant.

The concept of "test"

It means a technical action that makes it possible to check the engineering characteristics of an object (product), determine the degree of wear, quality and suitability for use. long-term use. Testing a prototype is permitted as per individual elements, and in the complex.

Test stages

There are departmental, interdepartmental and state acceptance tests. GOST 34.601-90 establishes the following types:

- preliminary;

- experienced;

- acceptance

Any of them requires compliance with a certain procedure, for which a special document is developed - an acceptance test program. It must be approved by the customer. The program specifies the scope of testing, both necessary and sufficient, ensuring the intended completeness of the results obtained and their reliability.

Preliminary tests should be carried out after testing and preliminary debugging of the equipment.

Pilot tests are carried out to determine the readiness of the equipment (machine, system) for continuous operation. Without these tests, acceptance tests are prohibited.

Final stage

These are acceptance tests. The path to life of the equipment (machine, system) being developed depends on them. This stage provides answers to the questions posed to designers. First of all, this is compliance with the given purpose, productivity and technical and economic efficiency, then whether it will correspond modern requirements safety precautions and contribute to improving the work of workers.

During acceptance tests, the following is checked:

- assessment of the success of completed pilot tests;

- making a decision on the possibility of launching equipment (machine, system) into commercial operation.

Acceptance tests are carried out at the customer’s site (and an existing one). To do this, an order or instruction is issued to perform the necessary work.

Both of these documents are written according to current regulations and standards developed for certain types of objects. They are approved by the ministries supervising design organizations.

The program details:

- the purpose of the upcoming work and its scope;

- acceptance criteria for both the object as a whole and its parts;

- a list of objects to be tested, as well as a list of requirements that the object must meet (necessarily with indications of the points of the technical specifications);

- test conditions and deadlines;

- material and metrological support for upcoming work;

- testing means: technical and organizational;

- methodology for conducting acceptance tests and processing the results obtained;

- names of persons appointed responsible for carrying out testing work;

- list of required documentation;

- checking its quality (mainly operational and design).

Depending on the technical and other characteristics of the research object, the document may contain these sections, but if necessary, they can be shortened or new ones introduced.

Package of documents for the development of the Program and methodology

Requirements for the design and content of these documents are regulated by GOST 13.301-79.

The list of documents for creating the Program and methodology is not constant. It varies depending on the relationship of the tested object to a particular ministry or organization. But in general case The following documents will be required:

- instruction manual;

- regulatory and technical documentation: technical conditions, standards, etc.;

- passport of the received object;

- documents on completed registration from the manufacturer;

- drawings and descriptions;

- factory test reports (for foreign manufacturers).

The program and methodology for testing work compiled and certified by the customer and Rostechnadzor specialists is registered with the Federal Agency.

Commission

For acceptance tests, it is formed by the relevant decree of the enterprise. The commission should include representatives of the supplier of components, the customer, the design organization, the developer, technical supervision authorities and organizations involved in installation and the commission is approved by the relevant ministry.

In its work, the commission uses the following documents:

- terms of reference for the creation of equipment (machine, system);

- preliminary test report;

- as-built documentation for installation;

- acceptance testing program;

- acts (if necessary);

- work logs from pilot tests;

- acts of acceptance and completion from them;

- technical documentation for equipment (machine, system).

Before acceptance tests, system documentation and technical documentation are finalized in accordance with the comments of the preliminary test protocol and the certificate of completion of pilot tests.

The manufacturer and design organization must provide acceptance committee:

- materials from preliminary tests;

- experimental objects that have successfully passed preliminary tests;

- reviews, expert opinions, patents, copyright certificates issued during acceptance testing for a development sample;

- other materials approved by test methods for certain types of objects and standard programs.

Examination

This is one of the main points of acceptance testing. They should not duplicate previous stages, and the timing of their implementation is compressed.

Acceptance tests include checking:

- quality and completeness of the implementation of the functions of the equipment (machine, system) in accordance with the technical specifications;

- work of service personnel in interactive mode;

- fulfillment of any requirement related to equipment (machine, system);

- completeness of operational and accompanying documentation and their quality;

- methods and means necessary to restore the functionality of an object after possible failures.

If two or more objects with similar characteristics are tested, then the same conditions are created for testing.

During acceptance tests, durability and reliability studies are not carried out, but the indicators obtained during the tests must be entered into the relevant reports.

End of testing

Acceptance tests are completed by technical examination. That is, the object is disassembled and installed technical condition its elements (assemblies), as well as the complexity of disassembling and assembling the entire research object.

Upon completion of the work, the commission develops and draws up a test report. Based on this, further acceptance will be made. If necessary, the commission determines the scope of modification of equipment (machine, system) and/or technical documentation, and also gives recommendations for launching the tested object into mass production.

If this is not possible, then the acceptance test report is supplemented with proposals for improving the product, repeated acceptance testing, or a requirement to stop work on the object.

Acts and results

Acts on acceptance of the object are approved by the management of the enterprise, which appointed a commission to conduct tests.

The acceptance testing methodology recommends, if necessary, that the results of the tests be reviewed at the scientific and technical council of the relevant ministry or enterprise developing the facility jointly with the customer (that is, even before the acceptance certificate is approved).

The decision to launch tested objects into series is made on the basis of materials and recommendations of the acceptance committee and/or scientific and technical council by order of the ministry. It must indicate the volume of production and provide recommendations for implementation.

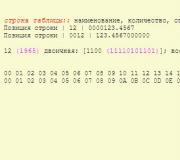

Acceptance test report

Four years ago, unified forms of primary documents were abolished. This gave organizations the right to develop custom templates any document. The main thing is to comply with the following requirements:

- The document is signed by all persons who compiled it. If one of them acts under a power of attorney, this must be reflected in the act.

- The legality of the act is not affected by whether it is drawn up on a regular piece of writing paper or on letterhead. As, by the way, whether the document is handwritten or typed on a computer (the main thing is “live” signatures).

- Stamps and seals are placed on the document if this is specified in the charter and/or accounting policy organizations.

- Logically, the act has three parts: the beginning (the so-called header - date, title, place of compilation), the main part and the conclusion.

The number of copies of documents is equal to the number of signatories. Each of them has the same legal status and identical text. Information about the act is entered into a specialized journal of the organization’s documentation.

There should be no errors or omissions in the acceptance test document. Because it can be not only the basis for placing an object on the organization’s balance sheet or writing it off, but also the main supporting document when handling statement of claim to the court.

The name of the document is written in the center of the page, below is the place of compilation (city, town, etc.) and date.

The main part of the act contains the following information:

- Composition of the commission. The enterprise (organization, ministry), representatives who will sign the document are indicated, then their positions and full last name, first name and patronymic.

- Name of the object and real address its installation.

- Detailed list of test work(formatted in the form of a list or table) with information about the test conditions.

- If deficiencies are discovered, they, as well as proposals for elimination, are included either below or in an appendix to the act.

- The acceptance test report (a sample is given below) ends with the commission’s conclusions about the capacity or incapacity of the tested object.

The opinion of any member of the commission, different from the rest, must be written down either in the act itself (as a separate paragraph) or in an appendix to it. All documents accompanying the act are also listed in it.

And only after this, all participants in the preparation of the document put their signatures and decipher them.

Completion of work

A signed act is included with the object being tested. The act is stored either in accordance with current legislation or in the manner established by the regulations of the organization.

Drawing up a test report is a necessary part of the procedure for checking equipment, devices, equipment or any materials. The protocol records all actions performed during the test, as well as their results. Tests may be mandatory or carried out on a voluntary basis. They can also be one-time or periodic.

FILES

The information included in the test report is confidential nature and should not be disclosed without the consent of the interested parties.

Purpose of the document

In manufacturing companies, testing is part of routine activities. They allow you to install:

- quality of manufactured products,

- determine the degree of its suitability for further use in different conditions, including non-standard ones,

- confirm its compliance with the declared properties.

The test report includes technical specifications object, all stages of verification, and then the results for each of them are summed up. The final part of the protocol includes a summary summary.

It should be noted that in some cases, enterprises engage other companies or specialized laboratories with necessary equipment and experience in testing certain objects - this practice is especially common if testing requires a special license.

Test procedure

The test, as a rule, is carried out by a commission appointed by special order of management. It includes specialists from specialized structural divisions of the organization who have the necessary qualifications and certain knowledge about the object being tested. Sometimes the commission includes outside experts who are able to assess the quality of the material at a higher level.

The tests simulate special conditions, which the equipment, machinery, and other objects undergoing testing must withstand. The entire procedure is recorded in the protocol. After this, the protocol is signed by the commission members or the responsible employee (the head of the organization).

It should be noted that test results can be either positive or negative - in both cases this must be included in the protocol.

If an object does not pass the test, it can be modified and sent for repeated tests.

Protocol validity period

This document is not valid for an indefinite period. The period of its validity for mandatory examinations, established at the state level, is determined by the time the tests are carried out.

- If this first time, then the validity period of the document is equal to one year,

- for any subsequent tests, the period of relevance increases up to six years.

In cases with private companies and products whose tests are carried out on the personal initiative of the organization’s management, the validity period of the protocol is determined on an individual basis.

Rules for drawing up a test report

To date, the test report does not have a standard unified sample that is mandatory for use. Enterprises and organizations can make it up free form, based on your needs or use a template developed within the company and approved in its accounting policies.

At the same time, there is a number of information that must be present in the protocol in any case. This:

- name of the organization conducting the tests,

- date of procedure,

- document number,

- name of the object (material, device, equipment, technology, etc.),

- its technical characteristics (power, weight, volume, etc.),

- test conditions (temperature, voltage, etc.).

Only reliable information should be included in the protocol; inclusion of unverified data or deliberately false information may lead to punishment from regulatory authorities.

Rules for drawing up a test report

The protocol template is usually printed on a computer; basic information can be entered into it either by hand or in printed form. It is permissible to draw up the document on a regular A4 sheet or on the company’s letterhead - the second option frees you from the need to enter the company details manually.

The protocol must be certified with the original signatures of the responsible persons.

At the same time, it is not necessary to put a stamp on it, since since 2016 the presence of seals and stamps legal entities is not a requirement by law (i.e. documents can be stamped only with the voluntary expression of the will of the company’s management).

The protocol is written in as many copies as necessary for all interested parties. After losing its relevance, the document is transferred for storage to the archive of the enterprise, where it is kept for the period established for such papers.

- At the beginning of the document, the name of the company that conducts the tests is indicated.

- Then a link is given to the number of the state license or certificate that allows you to conduct these tests.

- Next, enter into the form locality, in which the organization is registered, as well as the date of drawing up the protocol.

- Below, in the middle of the line, the name of the document is written indicating its essence.

- After this comes the main section. It is usually presented in the form of a table or individual paragraphs. This includes:

- name of the tested object,

- its technical parameters,

- date of manufacture,

- test date (day, month, year of start and end),

- number of samples

- test conditions are the most important part document, therefore it is described as carefully and in detail as possible.

- Next is the consequences of testing for strength, moisture resistance, etc. (depending on the purpose and testing methods).

- Finally, the form indicates the test results and provides a short summary of the product’s suitability for further use.

- The protocol must be duly signed indicating the position, surname, and initials of the persons responsible for the test.

Test report (TR) - a document that contains product test results. Issued by a testing laboratory accredited by authorized bodies to carry out testing of certain types of products.

Why do you need a product test report?

The test report is the basis for issuing or refusing to issue various permits, such as:

- Permission from Rostechnadzor

- etc.

Purpose of testing – confirm the ability of products to meet expected and required performance in certain conditions, by obtaining qualitative and quantitative characteristics by research methods.

To carry out testing and research, products are developed special programs tests. They are based on Technical specifications. Where possible, standard standard programs and test methods are used. If the test requirements are not standard, then new test methods and research programs are developed. New methods must undergo mandatory approval by authorities state supervision and other authorized bodies.

The product testing program contains mandatory verification and analysis of all technical documentation (design, operational, etc.).

The research methodology consists of:

- rules and conditions for testing;

- confirmation of properties, characteristics, indicators that are subject to evaluation;

- methods and methods for processing test results and methods for analyzing results with their evaluation;

- means of control and measurement used during testing;

- conclusions about the research results (test report).

Each type of product has its own testing methodology, which is prescribed in GOSTs, which establish the rules and methods for testing specific materials.

Product testing requires control samples, which will be subject to research. The selection of samples can be carried out by the applicant himself, or by a certification body, or by a testing laboratory or other authorized body, depending on the requirements and the type of permit for which the tests are being carried out.

Tests can be:

- destructive (the sample will not be suitable for further use)

- non-destructive (the sample will be suitable for further use)